Printed Circuit Boards (PCBs) work as the backbone of digital gadgets, playing a crucial role in connecting various elements like capacitors, resistors, and incorporated circuits. As modern technology remains to breakthrough, the demand for a lot more advanced PCB layouts has actually risen, causing the popularity of PCB assembly solutions and technologies in multilayer flexible PCBs. In this article, we will certainly check out these elaborate topics, delving right into the nuances of PCB design, the advantages of PCB assembly solutions, and the unique capacities of multilayer flexible PCBs.

The complexity of contemporary digital tools has actually necessitated more complex PCB designs. PCB design involves the format of the digital circuit on a board using various software application tools that assist in creating schematics and arranging the physical positioning of parts. Excellent PCB design can maximize the efficiency of the gadget and reduce the potential for failing, making it a vital element of creating electronic products.

In numerous cases, business choose for PCB assembly solutions to enhance their production processes. PCB assembly is the following step adhering to the design stage, where the developed boards are physically manufactured and populated with parts. Picking the right PCB assembly service can substantially affect the high quality and dependability of the final product.

One of one of the most interesting developments in the realm of PCB design is the arrival of multilayer flexible PCBs. These boards are functional and versatile, making them a superb option for applications where room is at a costs. Multilayer flexible PCBs incorporate the benefits of flexible and rigid circuits, allowing them to twist or bend without jeopardizing functionality. This characteristic is specifically important in industries such as electronic devices, automobile, and clinical gadgets, where parts have to fit right into compact and usually challenging areas. The design of multilayer flexible PCBs includes layering various substratums, generally a mix of plastic and resin materials, which permits greater circuit thickness and improved efficiency. The challenges of making multilayer circuits commonly focus around making sure that the layers are properly aligned which the wanted electric links are attained without disturbance. The production process must suit the delicate nature of flexible materials, leading to technologies in production techniques that make certain integrity while keeping versatility.

Flexible PCBs, particularly multilayer variations, have located a wide variety of applications across many markets. In the clinical area, for instance, they are frequently used in mobile tools, wearables, and advanced imaging systems because of their ability to satisfy the shapes of the human body and fit into tight areas. In the customer electronic devices field, flexible PCBs are made use of in smart devices and tablets, where they help lower the overall weight read more and density of gadgets while still sustaining high-density links. Automotive innovation also takes advantage of multilayer flexible PCBs, used in numerous sensors and control systems where versatility and light-weight products can add to enhanced automobile efficiency and fuel efficiency. This cross-industry utilization showcases just how multilayer flexible PCBs are pushing the borders of what is possible in digital design.

When considering PCB design and assembly solutions, it is additionally vital to keep in mind the readily available technology and materials that can improve check here item longevity and performance. The ongoing development in PCB products, such as high-frequency laminates, can dramatically impact the efficiency and dependability of circuits, particularly in high-speed and high-frequency applications. In addition, the unification of sophisticated production strategies, such as additive production and 3D printing, can better minimize production costs while allowing for more complex and customized styles.

With the raising focus on sustainability and environmental obligation, many PCB manufacturers are discovering environmentally friendly materials and processes. Innovations such as lead-free soldering and using recyclable substratums not only aid minimize the environmental footprint of digital products but can additionally work as a selling factor for ecologically mindful consumers. As laws around digital waste become extra rigid, adopting greener production methods can position firms favorably on the market.

Moreover, the increase of the Internet of Things (IoT) has changed the landscape of PCB design and manufacturing. With billions of connected gadgets currently a truth, the need for miniaturized, low-power, and highly trustworthy PCBs has risen. As IoT gadgets frequently call for specific wiring to sustain wireless communications and data handling, cutting-edge PCB styles must arise to satisfy this vibrant market. PCB assembly company are therefore tested to create remedies that not only satisfy typical performance metrics but additionally attend to the details needs of IoT applications, such as energy performance, real-time data processing, and smooth connection.

As technology races ahead right into the future, the advancing landscape of PCB design and assembly is becoming progressively complicated. Remaining ahead in this field needs ongoing education and adaptation to new innovations, methods, and products. For designers and manufacturers, maintaining close connections with PCB assembly company can assist in partnership and innovation, guaranteeing that items are at the forefront of technical innovations. get more info This collaboration can be crucial in browsing the ins and outs of modern PCB manufacturing, advancing the capabilities of layouts, and inevitably supplying remarkable products to a rapidly transforming market.

To conclude, the globe of PCBs is regularly developing, driven by technologies in design, assembly services, and the growing value of flexibility in multilayer circuits. By comprehending the intricacies of PCB design, leveraging high quality assembly solutions, and embracing sophisticated production services, techniques and designers can develop reputable and reliable electronic products. As we witness the interconnection of modern technology across various industries, the function of PCBs will only end up being a lot more substantial, leading the way for the future generation of electronic solutions. The obstacles of intricacy, sustainability, and miniaturization remain at the forefront, urging constant developments in this important and exciting field. Whether for consumer electronics, clinical gadgets, automotive applications, or IoT modern technologies, the continuous advancement in PCB design and assembly will play a critical duty fit the future of electronics. As we jointly move towards a more interconnected globe, the importance of taking on lasting methods and innovative services will certainly be critical, making certain that the industry continues to be capable and robust of fulfilling the demands of tomorrow's technological landscape.

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Jenna Jameson Then & Now!

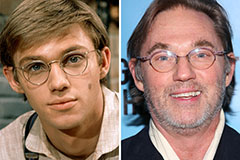

Jenna Jameson Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!